Broken glass? Soon, you could 3D-print a replacement. Discover the tech turning science fiction into reality for designers, engineers, and homes.

From Shattered Pieces to a Printed Future

That heart-sinking crash of glass on the floor is a universal experience. For centuries, the response has been the same: sweep up the pieces and buy a replacement. But what if your next step wasn’t toward the trash can, but toward a printer?

This is the promise of 3D-printed glass, a cutting-edge technology rapidly moving from high-tech labs into the realm of future possibility. It’s a field where scientists and artists are learning to tame one of humanity’s oldest materials, using light, heat, and computing power to build it layer by layer. This isn’t just about convenience; it’s a fundamental shift from mass production to personalized, on-demand creation.

The journey to print glass has been complex, but the breakthroughs are now stunningly clear. This article explores how it’s done, why it matters, and how it could reshape everything from art to optics.

How 3D Printing Works: A Quick Primer

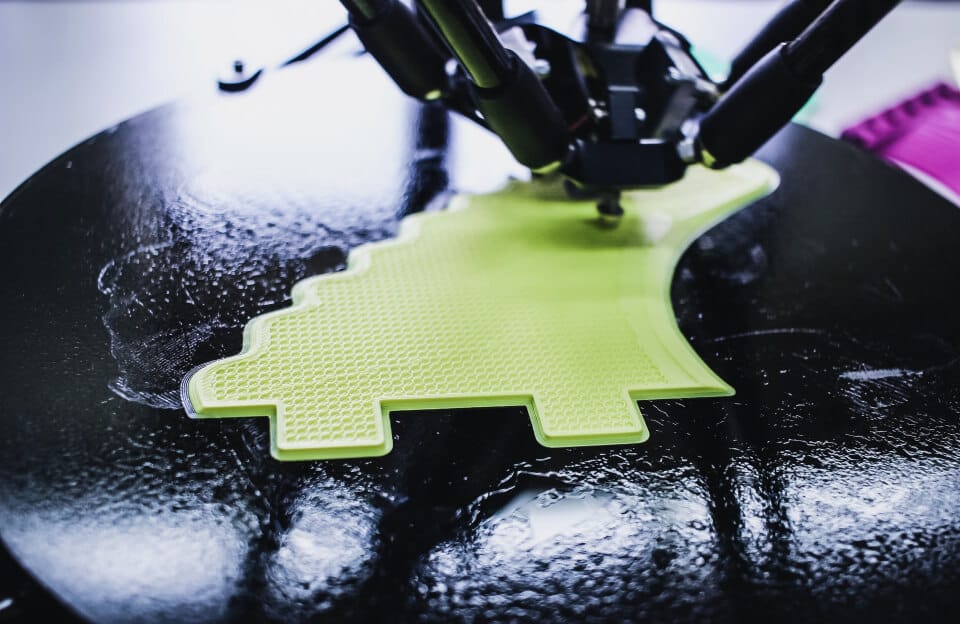

To understand the revolution of printing glass, it’s helpful to know the basics of additive manufacturing. Unlike traditional methods that carve away material (subtractive manufacturing), 3D printing builds objects from the ground up.

Common consumer methods include:

- FDM (Fused Deposition Modeling): Melts plastic filament and extrudes it through a nozzle.

- SLA (Stereolithography): Uses a laser to harden liquid resin into solid plastic.

- SLS (Selective Laser Sintering): Fuses powder particles together with a laser.

Glass, however, defies these simple approaches. Its unique properties have made it one of the final frontiers of additive manufacturing.

The Formidable Challenge of Taming Glass

Why has 3D printing glass been so difficult? Glass is not a forgiving material. Its very nature presents a series of high-stakes engineering puzzles:

- Extreme Heat: Glass melts at temperatures exceeding 1,000°C (1,832°F)—far beyond the capability of any desktop printer.

- Viscosity Control: Molten glass must be at a precise consistency. Too viscous, and it won’t flow; not viscous enough, and it becomes an uncontrollable drip.

- Thermal Shock: Glass must be cooled slowly and evenly in an annealing process to prevent internal stress from causing instant shattering.

- The Clarity Imperative: For most applications, the end goal is perfect transparency. Any imperfections, bubbles, or visible layer lines ruin the functional value.

For a long time, these challenges seemed insurmountable. But brilliant innovations have cracked the code, not with one solution, but with several.

How It’s Done: The Pioneering Methods

Researchers have developed multiple techniques to conquer these challenges, each with its own strengths.

1. Direct Molten Deposition: Robotic Glassblowing

Pioneered by MIT’s Mediated Matter Group, this method is a mesmerizing high-temperature ballet. It works like a robotic version of traditional glassblowing.

- The Process: A custom printer features a kiln filled with molten glass, mounted on a robotic arm. The arm moves the entire kiln, extruding a continuous filament of glass through a nozzle. The material is laid down in precise paths, fusing to the previous layer while still hot.

- The Key: This method exploits the glass’s natural viscosity at high heat, allowing it to hold its shape long enough to harden.

- The Result: It creates strong, complex, and beautiful forms impossible to make by hand. The object must then be annealed to relieve stress.

2. Binder Jetting: The “Glue and Bake” Approach

This indirect method cleverly avoids handling molten glass altogether.

- Step 1: Printing: A thin layer of fine glass powder is spread across a build platform. An inkjet print head then deposits a binding agent (a specialized glue) in the shape of that layer.

- Step 2: Repeating: The platform lowers, a new powder layer is spread, and the process repeats, building a fragile “green” object.

- Step 3: Firing: The piece is transferred to a kiln. The heat burns away the binder and sinters the glass particles, fusing them into a solid, transparent object.

3. Vat Polymerization: Transforming Resin into Glass

This is one of the most promising methods for achieving high detail and clarity, led by companies like Glassomer.

- The Special Resin: A liquid resin is infused with nanoscale glass particles and a light-sensitive plastic binder.

- The Printing: This resin is used in a standard SLA or DLP 3D printer. A UV laser cures the resin, hardening the plastic binder and trapping the glass particles in the desired shape.

- The Magic: The plastic object is placed in a furnace. The heat burns away all the plastic and sinters the remaining glass nanoparticles into a pure, fully dense glass object.

(Strategic Internal Link)

The principles of sintering aren’t unique to glass. Discover how this same process is revolutionizing metal 3D printing in our article on The Future of Manufacturing.

Far Beyond a New Wine Glass: Transformative Applications

While printing a replacement cup is a relatable example, the true potential of this technology is transforming entire industries.

1. Unleashing Art and Architectural Design

Artists and architects are no longer constrained by the limits of molds and blowing. They can now create:

- Unimaginable Forms: Complex, organic lattices and scaffolds that play with light in entirely new ways.

- Custom Lighting: Beautiful, one-of-a-kind lampshades and light fixtures with intricate internal structures.

- Architectural Features: Unique textured panels and facades for buildings that create dazzling visual effects.

2. Revolutionizing Optics and Photonics

This is perhaps the most significant application. The ability to print precise glass components is a total game-changer.

- Advanced Lenses: Printing lenses with “freeform” geometries that are impossible to grind traditionally. This is critical for better cameras, microscopes, and AR/VR headsets.

- Microfluidic “Lab-on-a-Chip” Devices: Tiny, complex channels can be printed inside clear glass for medical diagnostics, allowing doctors to test tiny fluid samples with light.

- Fiber Optics: Pioneering new ways to create and integrate components for faster data transmission.

3. Advancing Medical and Biotechnology

The biocompatibility and clarity of glass make it ideal for medical use.

- Custom Implants: Patient-specific glass-based implants that can be designed to encourage bone growth.

- Precision Lab Equipment: Researchers can print custom beakers, flasks, and complex apparatus on demand for specific experiments.

The Current Hurdles: What’s Holding Us Back?

We are not yet at the consumer “print-a-glass-daily” stage due to a few key limitations:

- Cost: The printers and materials remain prohibitively expensive for homes.

- Speed: The printing and, especially, the slow post-processing (sintering, annealing) can take many hours.

- Surface Finish: Achieving optical clarity that rivals polished molded glass remains a challenge for some methods.

- Size: Most printed glass objects are still relatively small, limited by the size of the printers and kilns.

The Transparent Horizon: What’s Next?

The trajectory, however, is clear. As technology advances, costs will fall, speed will increase, and quality will improve. We can anticipate:

- Multi-Material Printing: Printing objects that combine glass with other materials, like metals or electronics, in a single process.

- Specialized Home Use: Desktop glass printers could become a reality for dedicated hobbyists and designers.

- Ubiquitous On-Demand Manufacturing: Dental labs printing custom crowns, opticians printing unique frames, and artists selling digital files instead of fragile physical goods.

Conclusion: Building a Future, Layer by Layer

The story of 3D-printed glass is more than a technical manual; it’s a narrative of human ingenuity. It represents the reinvention of an ancient material for a digital age, shifting the paradigm from mass production to personalized creation.

The next time you hear that dreaded crash, let it be a reminder. You’re not just hearing the end of something old. You’re hearing the echo of a future being built—a transparent, customizable, and incredibly exciting future.